Dodatne informacije

| Teža [kg] |

5.2600 |

| Hide Product Prices |

Da |

| Velikost krogle [mm] |

50,8 |

| Material |

Tip 13 - Nosilna krogla iz ogljikovega jekla, ohišje iz pocinkane pločevine. |

| A - Maksimalni premer [mm] |

101,6 |

| B - Delovna višina krogle [mm] |

109,1 |

| S - Od podlage do vrha telesa [mm] |

84,1 |

| L - skupna dolžina [mm] |

159 |

| N - dolžina navoja [mm] |

49,9 |

| P - velikost navoja |

1" |

| Največja dinamična obremenitev [kg] |

2000 |

| Proizva. |

ALWAYSE |

| C - Izpostavljenost krogle izven obroča [mm] |

14,3 |

| X - Dimenzije med sloji |

38 |

| Tarifna št. |

84832000 |

| Država izvora |

GB |

Opis produkta

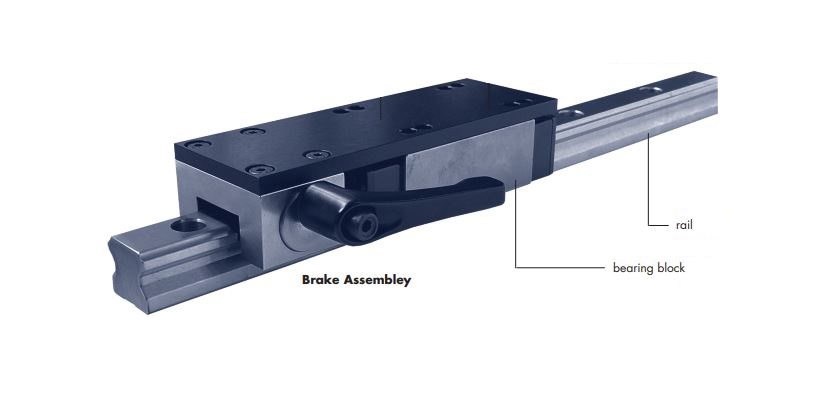

Alwayse 7173 Type 13 - Carbon Steel Balls

Features: High load capacity, bolt fixing. Two spanner flats for fixing and removing. Drill hole fixing. Maximum tightening torques range from 15Nm for M8 to 25Nm for M24.

ALWAYSE Hevi-Load Units are designed and manufactured to precise standards. They offer the highest performance available in load transfer applications with load ball sizes from 12.7mm to 50.8mm diameters

and a load capacity range from 35kg to 2000kg used either ball up or ball down.

Hevi-Load Units run on the re-circulating ball principal. The load ball rotates on a bed of small balls supported on a hardened steel, precision machined table.

They can work at maximum capacity in temperatures from - 30 c to +100c. Drain hole or grease points can be incorporated on request.

No spanner flats for 7110 and 7106 Hevi-Load Units. *Models marked with an asterisk have a bearing shell and are assembled with no felt seal with a chemical black finish for Types 13 and 16.

Type 15 Units (all stainless steel) available on request. When using stainless balls, reduce Type 13 load capacity by 33.3%.

All units are machined using CNC machines from one piece of steel, therefore flanges and threads are integral.

All hevi-load units have a electropharetic black coated body for corrosion resistance

Podjetje Alwayse Engineering Limited je vodilni proizvajalec skodeličnih ležajev na svetu. Ustanovljeno je bilo v Birminghamu v Združenem kraljestvu leta 1939, ko je bilo kupljeno majhno inženirsko podjetje Sheridan Tools. Kasneje so njegovo ime spremenili v "Alwayse", kar pomeni, da so skodelični ležaji večsmerni in se premikajo v vse smeri ali načine - torej "Alwayse". Razločno črkovanje prispeva k individualnosti podjetja. Kot začetniki skodeličnih ležajev pred več kot 70 leti je Alwayse postal bistveni del industrije za ravnanje z materialom. Skodelični ležaji Alwayse, izdelani iz visokokakovostnih materialov v tovarni v Birminghamu, se uporabljajo v vseh sektorjih po vsem svetu in vsako leto se jih proda več kot 2.000.000.

KAKOVOST

Alwayse Engineering Limited je sinonim za kakovost, kar potrjuje tudi pridobljen cetifikat ISO 9001. Alwayse ima politiko nenehnega izboljševanja ponudbe izdelkov z novimi inovativnimi in kreativnimi idejami z uporabo najnovejših strojev CNC in proizvodnih/kontrolnih metod. Posebej zasnovani stroji za testiranje skodeličnih ležajev, ki se redno uporabljajo za testiranje proizvodov, skupaj z dolgoletnimi raziskavami in izkušnjami zagotavljajo zmogljivost svetovnega razreda.

Dostava

Če naročenega blaga ne morete prevzeti v naši trgovini, vam ga pošljemo po pošti z DPD-jem.

Strošek poštnine po Sloveniji za pošiljke do 30 kg znaša 4,235 EUR/pošiljko+DDV.

Strošek dostave z odkupnino znaša 4,235 EUR/pošiljko+DDV.

Za daljše blago znaša doplačilo:

>2000 do 3000 mm: +40 EUR+DDV

>3000 do 4000 mm: +60 EUR+DDV

>4000 mm: +80 EUR+DDV

Če želite naročeno blago dobiti še isti dan, vam proti plačilu nudimo tudi osebno dostavo.

Plačilo

Možni načini plačila:

- PayPal

- kreditna kartica

- bančno nakazilo

- po povzetju